“GEORGI SIMEONOV–ELECTRICAL ENGINEERING AND AUTOMATION”

COMPANY PRODUCTS AND SERVICES PRESENTATION

ET “GEORGI SIMEONOV–ELECTRICAL ENGINEERING AND AUTOMATION”

1172 Sofia, , Bulgaria, jk.Dianabad, Bl.23 Entr.A/B/V

Tel. 00359 2 962 52 29 Tel./Fax 00359 2 862 0246

Mobile : 00359 888 963 924

e-mail: gsea@abv.bg INTERNET : http://www.gsea.biz/ Sofia, 10.05.2010

INDUSTRIAL PRODUCTS

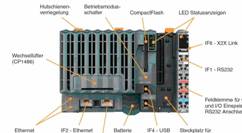

Control Systems

I/O Systems, Distributed I/O on open fieldbuses

SCADA Systems

Industrial PCs

Operator Interface

Safety Technology

Motion Control

Industrial Networking /EPL/ & Fieldbus modules

Industrial Software

Process Control, Factory Automation

Accessories

|

Drive systems

|

Control Systems PLC

Servo systems

|

|

Industrial IPC

|

Operator Stations

|

Integrated solutions :

PLC + Servo drives + Visualization + Programming , from B&R

PLCs for the packaging, plastics, printing and paper, textile, automotive, food and beverage, semiconductor, wood, metal and mining, pharmaceutical, chemical, oil an gas, process automation, robotics, power generation.

System Integration with components of B&R / Baumer electric / Baumueller Nuernberg /Lenze / Norgren / ABB / Omron / Phoenix Contact / Scneider electric / Siemens / WEG / WAGO / RITTAL / PILZ /

Safety technology by B&R and PILZ

Motors

|

Three-Phase Motors Single-Phase Motors Worm/Spur Geras Geared Motors DC – Motors Electromagnetic Brakes

|

|

|

When ordering motors, the

following data is required /Ordering data/ :

type / voltage / frequency / speed / output / operating mode / protection / mounting

installation position

When ordering gear units, the following data is required:

Type / gear ratio i = x:y / mounting position

Process Control, Factory Automation

SCADA Systems

INDUSTRIAL SENSORS

Sensor solutions

Inductive sensors

Photoelectric sensors

Fiber optic sensors & cables

Capacitive sensors

Magnetic sensors

Ultrasonic sensors

Encoder / Motion control

NAMUR Sensors

Magnetic Sensors for pneumatic cylinders

Force and strain sensors

Smart vision sensors

Distance sensors

Pressure sensors

Laser sensors

Precision limit switches

AS-I , Actuator Sensor Intrface

Fork and angle sensors

Hall sensors

When ordering sensors, the following data is required /Ordering data/ :

Dimensions / type / voltage / frequency / speed / output / operating mode / protection /

mounting installation position

INDUSTRIAL MACHINES

1. For Woodworking Industry:

Palletizing machines

Cutting machines

CNC Processing machines

Sanding machines

Drilling machines

Drying machines

Gluing, Milling machines, Varnishing robots

New machines and retrofit of existing machines /electrical control boxes, PLC, programming, commissioning , mechanic, pneumatic /

/ See the pictures ! /

|

Drying machines

|

Varnishing robots

|

|

Sanding machines

|

Palletizing machines

|

2.For the metal industry

Casting Milling

Die-casting Turning

Welding Grinding

Cutting Robotics

Bending CNC

/ See the pictures ! /

|

Welding robots

|

Grinding machines

|

Bending , with robots

|

|

Die-casting

|

Turning

|

Bending /pipe, wire/

|

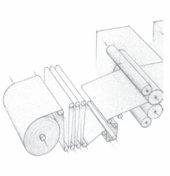

3.For the plastic industry

Extrusion machines

Winding machines

Blow molding machines

Pressing and molding machines

Thermoforming machines

New machines production / system integration, delivering, commissioning, as well as retrofit of existing machines /electrical control boxes, PLC, programming, commissioning , mechanic, pneumatic /

/ See the pictures ! /

|

Extrusion machines

|

Pressing and molding machines

|

|

Dosing unit

|

Winding machines

|

4.For the packaging industry

Forming & Filling Sealing

Filling & Dosing Blister Packaging

Labeling Wrapping

Cartoning & Palletizing

|

Filling & Dosing

|

Cartoning & Palletizing

|

Labeling

|

|

Blister Packaging

|

Wrapping

|

Forming & Filling

|

New machines system integration and production, delivering, commissioning, as well as retrofit of existing machines /electrical control boxes, PLC, programming, commissioning , mechanic, pneumatic /

Examples

5.Solutions for the Printing industry

Web-fed offset printing

Sheet-fed offset printing

Product printing

Packaging of printed products

Folding

Inserting and gluing

Conveying and storing

Addressing , Stacking

A. New machines system integration and production, delivering, commissioning.

B. Retrofit of existing old printing machines /electrical control boxes, PLC, programming,

commissioning , mechanic, pneumatic /

Customer’s reference list

|

Computer to plate

|

|

Winding

|

|

Conveying and storing

|

Stacking and palletizing

|

Inserting and gluing

|

|

Register control

|

|

|

6. ENERGY

Transformators 110 kV/20kV/0,4 kV

Transformator stations

Remote control

Power factor correction system / cos Fi regulators

PHOTO VOLTAIC -SOLAR COMPONENTS

Solar Panels, Inverters, Batteries & Enclosures,

Charge Controllers, Monitor & Meters, Wire and Connectors

Mounting, Commisioning

|

|

|

7. For all industries – universal transport solutions

BELT CONVEYORS

It is a general transfer system. Belt is choosen ( PVC, rubber, PU, Teflon, Plastic Modular Belt) according to product features which will be conveyed and belt is used on aluminium or steel construction and convey the products. Driving is made with motor reductor with chain transfer or direct couple wheel axle. For special application it can transfer the product as inclined. In case of gliding of products can be putted profiles

and product can be conveyed as diagonal.

ROLLER CONVEYORS

Roller Conveyor is produced according to using purpose as rubber covered and galvenized covered. Usually produced as aluminium construction but also produced according to demands as colored steel construction. With transmission chain or with belt which rubbed from the bottom side, action conveyed to roller by motor An ideal conveyor system for cardboard or styrofoam packs transportation and assembly lines where the

smooth bottom surface products are conveyed. Speed can be adjustment if different belt speed demands by frequency inverter. Product can be stopped in any requested point in according to distance of product with pneumatic stoppers by accumulation system. To take advantage of distance of the rollers can be putted 90° transfer unit or turning units inside.

TURNING UNIT

It is a system which allows to product or pallet to turns in demanded angle. Product with pallet goes up from the Conveyor as pneumatic , It is turned as automatic or manual with 90° - 180°- 270° - 360° angle. All of this process will be made as PLC or operator control according to automation.

PNEUMATIC TRANSFER UNITS

These type of the systems are used to direct the product flow on lines 90° left or right and can be integrated to conveyors . It is manufactured

according to the load with power transmission belts or chains. The unit is lifted 50 mm pneumatically and transfered 90 ° vertically to the conveyor in which the the unit is mounted.

PRODUCT TRANSFER MANIPULATORS

Due to increasing customer demands to satisfy the necessity the robotic systems are developed GSEA Company is so pretentious about maniplators designs and production for different deprivations. These applications are especially for the finished product transfer without manuel in order to put in packing cartoons or styrofoam or in order to provide automatic consolidation of two different product groups.

PALLET CONVEYOR

Pallet conveyors are prefered with acetal pallets due to their quiet working in damp and watery enviroments, they are prefered with stainless steel pallets in hot material outputs. Pallets can be manufactured from 24 mm. to 304 mm. in width and can be produced straight , horizontal and radius with flexible dimensions. Pallets can be multi row side by side. Chassis can be stainless steel or painted steel.; metal equipments can be galvanised due to intended use. According to customers demands constant velocity or variable velocity motor can be used.

ELEVATOR

Altough elevators have similar mechanical features, they can have differences due to intended use. Usually they are used to convey end products to storage. Besides they can be used to bring the product up and down on a platform. They work with counterpoise system. It is driven by motor with carrier chain. Up and down movement of the elevator can be obtained by the means of bidirectional work of the motor.

OTHER TRANSPORT LINES & CONVEYORS – BY REQUEST

8. For all industries – small universal cars, electric drive,

hydraulic functions, for loading and unloading operations

Sample:

9. For all industries - FREQUENCY INVERTERS

10. For all industries - Application Software

SQL server and programming: MS SQL Server (T-SQL, Administration), Oracle

(plsql, administration), OS: Windows 2003 and 2008 (installation and administration)

Programming languages, tools and technology: VB, PHP, Java, JavaScript, C#, HTML, CSS, Ajax, .NET Framework, MS Visual Studio 2005 and 2008

IT-Security Systems-Software, Instalation, Training , by www.infoprocess.com.au and PACOM, AUSTRALIA

STANDART SOFTWARE

Web Servers, SQL Servers , Web Applications, Electronic Document Management Systems, ERP, Electronic Banking and System Integration

Certified by:

- BERNECKER+RAINER_INDUSTRIE ELEKTRONIK GmbH

- MUELLER MARTINI AG & MAN ROLAND AG

- SIEMENS SIMATIC S5/S7

- SCHEIDER ELECTRIC Modicon

- BAUMUELLER NUERNBERG

- FESTO/SKF

- MICROSOFT

- UNIX / LINUX / C++

Customers in Bulgaria :

Printing house Demax

Printing house Rotopress

Printing house BNB

Printing house Sofia

Printing house Varna

Printing house Exprint

Printing house PrintEx

IVAS TECH Ltd

CARLSBERG

ACTAVIS

EPIQ

BELAZ Sofia

AUTOMATION SOFTWARE : Automation Studio by B&R

Programming, Remote Diagnostics On-Line

Software from Siemens : Simatic STEP7/ STEP5/

Software from Scnheider: PL7

Industrial Networks with Ethernet POWERLINK,

Fieldbuses PROFIBUS/DEVICE NET/CAN Open

Sofia, 10.05.2010

------------------------------------------------------------------------------------

“GEORGI SIMEONOW–ELEKTROTECHNIK UND AUTOMATION” EÒ

Sofia, PLZ 1172, Bulgarien, jk.Dianabad, Bl.23 Eing.A/B/V

Tel. 00359 2 962 52 29 Tel./Fax 00359 2 862 0246

Mobile : 00359 888 963 924 USt.-Id.Nr.BG131360307

e-mail: gsea@abv.bg

INTERNET : http://www.gsea.biz/